At Pactics we work primarily with microfiber, a high-quality fabric that offers the highest standards in both efficiency and customisability. We have dedicated a great deal of time to understanding the potential of this innovative fabric, and so wanted to share with you a little of the science behind microfiber’s magic.

Microfiber is synthetic, and is made when extremely fine polyamide (nylon) and polyester threads are combined to create one single thread. Each of these threads is 100 times thinner than a strand of human hair, and 20 times thinner than a single strand of silk.

How It Works

During the manufacturing process these already-fine threads are split, which produces multi-strand fibres that resemble an asterisk shape when seen in cross-section (under a microscope). The many ‘arms’ of these asterisk-like strands are part of the reason microfiber is so excellent for cleaning, as they are able to sweep under particles of dirt, scooping them up and away from the surface in a way that regular (round) cotton fibres cannot.

When these split fibres are woven together to create cloth, their unique shape means that millions of microscopic pockets are created. After being scooped up dirt, oils, and microscopic debris then become trapped in these microfiber pockets, and remain there until the cloth is washed. This means that unlike traditional cleaning materials, microfiber cloths actually remove dirt and dust from – for example – a sunglasses lens, rather than simply push it around the surface. Microfiber can, in fact, carry up to five times its own weight in fluids!

Why Microfiber?

Not only does microfiber cloth store the dirt and grime that people want to remove from items such as sunglasses and camera lenses, it actually attracts it. Oil and grease are attracted to polyester and water is attracted to polyamides, the two key components that make up microfiber. In addition, when microfiber strands rub together they create a static charge, which can reach into cracks to attract and remove even more dirt. All that remains is a surface that is clean and completely smear-free.

Not only does microfiber cloth store the dirt and grime that people want to remove from items such as sunglasses and camera lenses, it actually attracts it. Oil and grease are attracted to polyester and water is attracted to polyamides, the two key components that make up microfiber. In addition, when microfiber strands rub together they create a static charge, which can reach into cracks to attract and remove even more dirt. All that remains is a surface that is clean and completely smear-free.

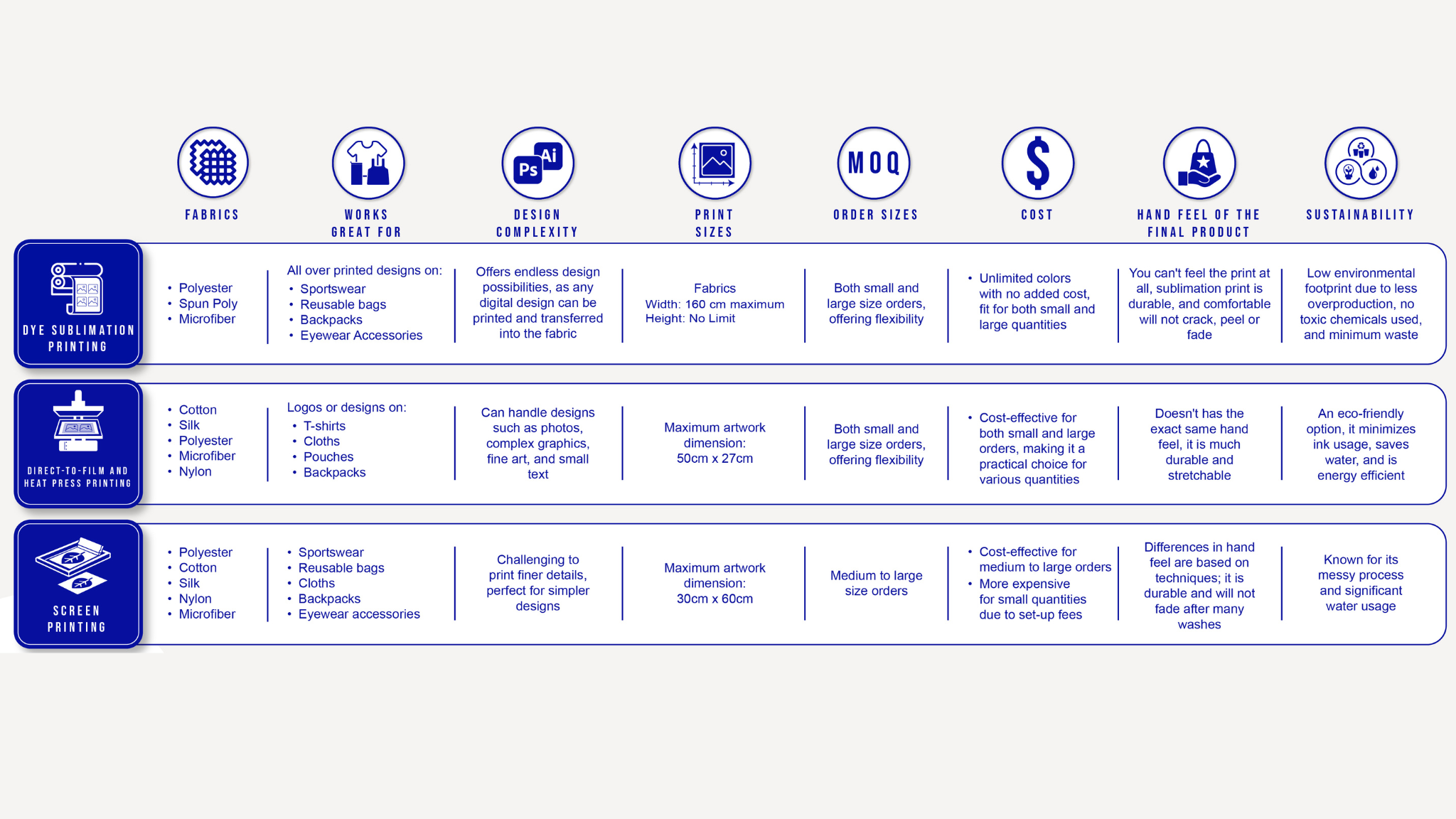

Due to the millions of tightly-woven fine threads, microfiber cloth has a smooth surface that doesn’t shed lint and won’t scratch or damage delicate items. This also creates the ideal surface for the range of creative techniques we use at Pactics, including sublimation, screen-printing, and embossing. Dyes adhere particularly well to microfiber, allowing us to meet branding needs with both vibrant colours and intricate designs.

We are continuously researching and developing innovative new ways to work with this incredible material, ensuring that our clients are always at the cutting edge of its ever-increasing potential. For more information on our work with microfiber, please check out latest CSR magazine.